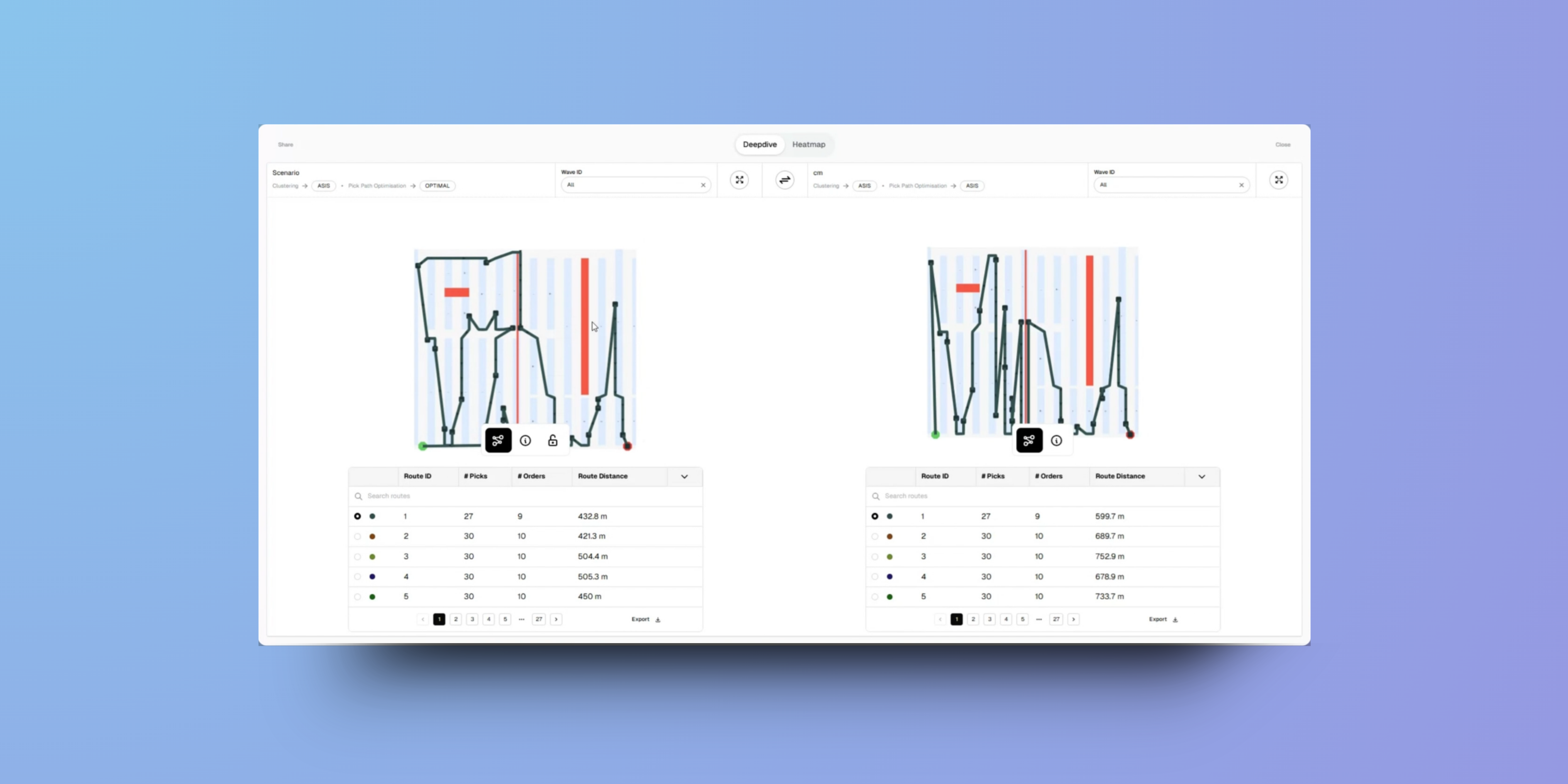

A digital warehouse map captures aisles, racks, movement rules, and constraints, giving optimization software the foundation to calculate the shortest pick paths, create smarter clusters, and test slotting strategies.

Learn how Warehouse Optimization Software (WOS) improves picking, packing, slotting, and data capture on top of your existing WMS system.

Compare mobile vs static dimensioning solutions for warehouses. Explore key differences between Optioryx and Cubiscan in setup, cost, and flexibility.

Learn strategies for preparing your warehouse for peak season. Discover how optimization techniques improve efficiency and reduce walking distances

Compare cluster vs batch picking in warehouses. Learn how they impact labor, speed, and complexity.

Cut warehouse order picking walking distances by up to 55%—without robots or layout changes—using smart, practical optimization strategies.

Learn how smart order batching can double your order picking rates. No robotics. Same efficiency.

Learn about batch vs. zone picking strategies, their pros and cons, and how smart algorithms 2x pick rates & improve efficiency in your warehouse

Mobile dimensioning — fast, accurate, and flexible. Learn how mobile dimensioning simplifies data capture.

Discover the best dimensioning solution for your warehouse. Compare manual, static, and mobile handheld dimensioner

Optimize warehouse operations with AI-powered digital twin. Cut walking distances by 50% and turn data from your WMS into actionable insights.