Compare cluster vs batch picking in warehouses. Learn how they impact labor, speed, and complexity.

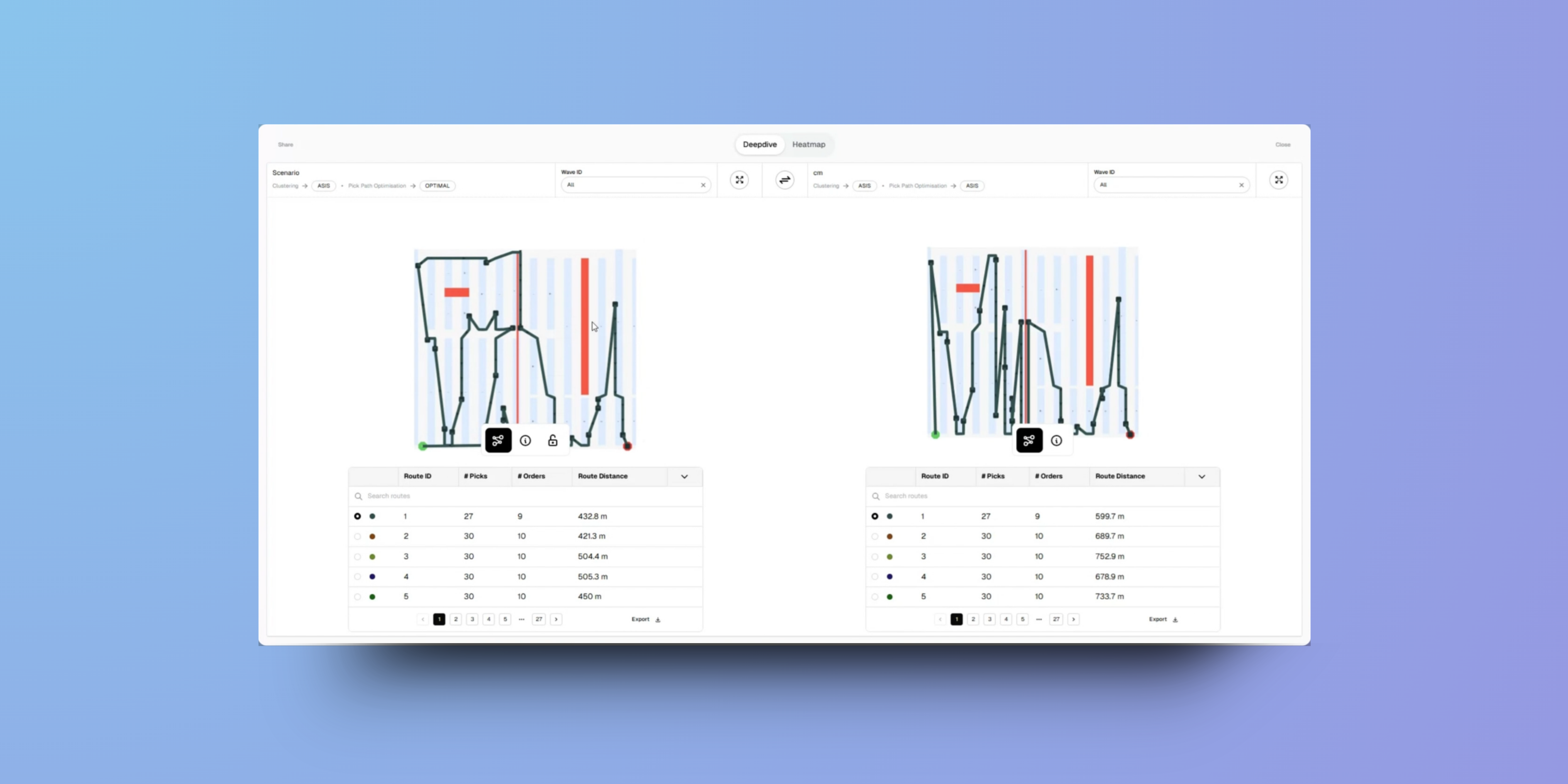

Cut warehouse order picking walking distances by up to 55%—without robots or layout changes—using smart, practical optimization strategies.

Learn about batch vs. zone picking strategies, their pros and cons, and how smart algorithms 2x pick rates & improve efficiency in your warehouse

Learn how smart order batching can double your order picking rates. No robotics. Same efficiency.

Replenishment is the key to warehouse efficiency. Learn why and how to improve your process for better inventory flow and fulfillment operations.

Optimize warehouse operations with AI-powered digital twin. Cut walking distances by 50% and turn data from your WMS into actionable insights.

Storage Location Assignment Problem (SLAP) in the context of warehousing involves the allocation of products to specific storage locations within a warehouse.

Picking performance is a key metric used in warehouses to measure the efficiency of outbound operations

Warehouse management systems lack optimized solutions for tasks like picking, which can significantly increase warehouse picking productivity

Discover how warehouse digital twins transform warehousing by providing a risk-free playground to explore what-if scenarios

Wave picking optimizes order fulfillment by grouping orders for efficient picking. Ideal for high-volume warehouses.

Cluster picking is a picking strategy where workers pick items for multiple orders simultaneously.